Plywood vs Chipboard – Which Is Better, Pros, Cons & Uses

Whether you need to choose a material for your sub-flooring or are contemplating buying a piece of furniture made out of plywood, you may have been wondering what the difference is between chipboard and plywood.

The fact of the matter is that they have many similarities. They are even used for some of the same kinds of things. Make no mistake about it though; they are different. In the following article we will be going through the differences between chipboard and plywood so you can make the right choice for your needs.

Overview Of Plywood Vs Chipboard

People often have cause to ask the question “what’s the difference between plywood and chipboard?” because both of these materials are used to build many things.

They are both wood products and are used to make things like furniture and flooring.

They are both also very common. Builders like to use these wood products because they are lightweight and inexpensive.

They are perfect for ready-made furniture (pretty much anything you get from Ikea is going to be made from one of these materials).

What Is Plywood?

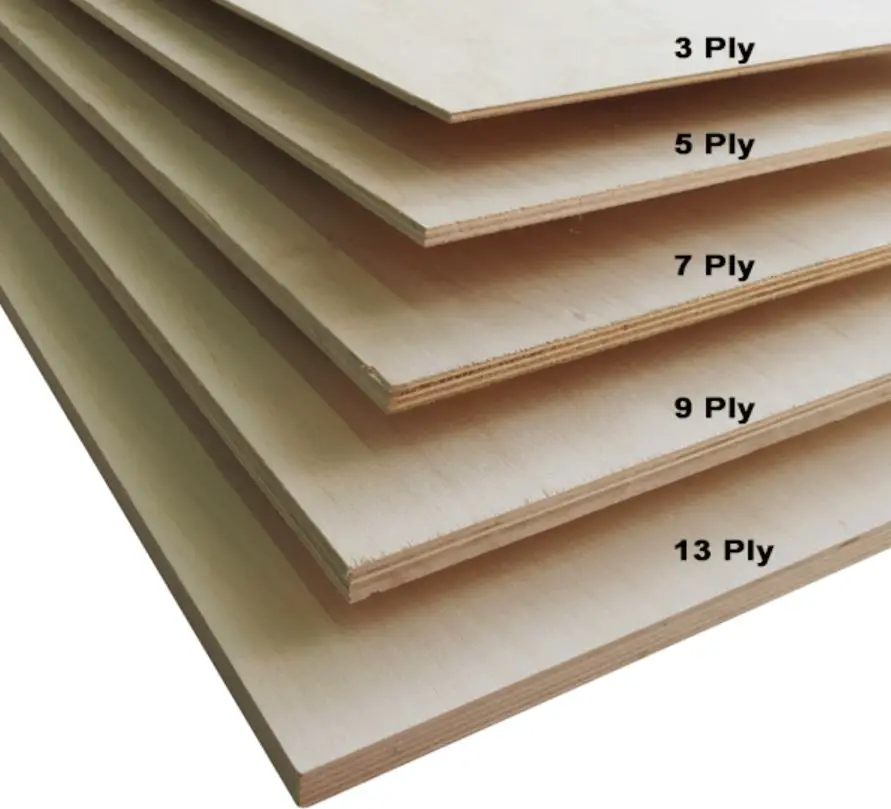

Plywood is a wood product that is made from thin veneers of normal, milled wood.

Multiple plies are compressed together with some sort of adhesive (the adhesive used will depend on the grade or quality of the plywood).

Plywood, like chipboard, is considered an engineered wood product because it has to undergo a manufacturing process before it’s ready for market.

What Is Chipboard?

Chipboard is an engineered wood product similar to plywood.

However, instead of using long, thin planks, chipboard (sometimes called particle board) is typically made from wood chips, small wood waste materials, saw dust and a resin to hold it all together.

Chipboard is made up of wood waste products and essentially, glued together to make functional boards that can be used much in the same way as Plywood.

Quick Comparison

Chipboard |

Plywood |

|

Affordability |

More affordable than plywood | Typically more expensive than chipboard |

Lightweight? |

Yes | Yes |

Multiple Types? |

Fewer than plywood | Many types |

Moisture Resistance |

It can become compromised when exposed to moisture | It holds up better to moisture than chipboard |

Plywood Details

One of the most important manufacturing features of plywood is that it is made in a hydraulic press with grains running perpendicular between layers.

For example, one thin veneer layer is oriented with the grain running left to right while the one on top of it is oriented with the grain running up and down.

And so on and so forth. They layers are then compressed together with an adhesive to bind the layers together.

This manufacturing process is called cross-graining and it enhances the strength of the wood product because wood is prone to splitting along lines of the grain.

Since plywood has no consistent parallel grain lines, it doesn’t split as easy as chipboard or even regular wood.

Plywood Uses:

Thanks to it’s strength, affordability and the many ways it can be treated (weatherproofing, insect-proofing etc.) plywood is used for many thing including but not limited to:

- Sub flooring for engineered wood flooring

- Wall supports

- Roof decking

- Shipping crates

- Cabinets

- Shelving

- Furniture

Chipboard Details

Basically any wood waste product can be used to create chipboard. Anything that cannot be used for anything else during the wood milling process can essentially be used to make chipboard or particle board as it is also called.

The wood waste material is mixed with resins to hold it together and various chemicals to make it more resistant to water and insects. This forms a liquid mixture that is poured into a mold to create a single sheet.

Once the mixture is cured, it form a hardened board that can be used for many applications including but not limited to:

Chipboard Uses:

- Wall bases

- Counter tops

- Flooring protection

- Underlayment

- Furniture

- Work benches

- Interior cupboards

Pros and Cons of Plywood

Pros:

- It can be used for a variety of applications

- The cross-graining gives it more rigidity than chipboard

- It’s better for holding onto screws and nails

- Stands up better to moisture

- There are many different types and grades of plywood

- It’s typically lighter than chipboard

Cons:

- It tends to be more expensive

- Not great for certain specialty projects like speaker cabinets

- It’s not as environmentally friendly as chipboard

- Lower grade plywood may have knots

Pros and Cons of Chipboard

Pros:

- Less expensive than plywood

- Chipboard manufacturing produces a denser core

- It’s made of waste material so it’s better for the environment

- Lightweight

- Chipboard tends to be smoother than lower grade plywoods

- It can be manufactured to repel insects

Cons:

- It tends to expand and warp when exposed to moisture

- Not great at holding onto nails and screws

- Generally not suitable to support anything that’s excessively heavy

- It can also discolor when exposed to moisture

What Are The Different Types Of Plywood?

We mentioned earlier that there are different types of plywood. To be more specific; there are different grades of plywood. The grades generally correlate with the quality of the plywood. They are divided into 4 grades:

Grade A

Grade A is the highest quality plywood. The surface of grade A plywood has been sanded so it’s ready to be painted over, features little to no knots, has little to know splits.

Grade B

Grade B is a step down from grade A and may feature a few minor splits and small knots.

Grade C

Grade C is likely to have knots that are 1 to 1 ½ inches in diameter. Some of the wood may also be discolored.

Grade D

Grade D plywood will have knots that are about 2 to 2 ½ inches in diameter and some splits in the wood.

When To Use Chipboard Over Plywood

Because the core density of chipboard is higher than plywood, chipboard is ideal for acoustic resonance.

Many people use chipboard to build speaker cabinets. Chipboard is also the go-to material for finish carpentry because it is cheap and can be used for non load-bearing construction.

When To Use Plywood Over Chipboard

Plywood is the better choice for residential and commercial construction.

It can be used to support walls, as roof decking and works great as kitchen sub flooring.

It is more resistant to moisture than chipboard so it is better to use it where moisture is common.

Which Costs More?

Plywood varies in price depending on thickness and treatment but it is generally more expensive than chipboard.

A 4×8 sheet of treated 3/8” thickness plywood will typically cost between $40 and $50.

Which Is Stronger?

Plywood is definitely stronger than chipboard.

Chipboard tends to be softer and more brittle than plywood because of the manufacturing process and the fact that it is not cross-grained.

Which Weighs More?

Plywood tends to weigh less than chipboard because the core of plywood is not as dense as chipboard.

Which Is Better For Flooring?

Plywood tends to be a better choice for flooring because it does not draw in moisture and deforms the way chipboard does.

Which Is Better For Cabinets?

This is a matter of debate. Chipboard can be stained and lacquered to give it a smoother finish.

Plywood has rougher fibers that can be hard to work with in cabinetry.

Plywood is the sturdier material so it is often used in higher-quality cabinets that are built to last.

Which Is Better For Roofing?

Plywood is better for roofing because it can bear more of a load than particle board.

It’s also lighter which makes it easier to hoist up onto a roof during construction or replacement.

Melamine Chipboard Vs. Plywood

Melamine is essentially chipboard with layers of wood thermally fused onto it. This gives it a harder, smoother surface.

It comes in a wide variety of colors and finishes and the surface cleans better than plywood.

However, melamine chipboard is heavier than plywood and still isn’t as strong.

MDF Vs. Plywood Vs. Chipboard

MDF (medium density fiberboard) sits between chipboard and plywood in terms of strength.

While it holds screws better than chipboard, it still isn’t as suitable for screws and nails and plywood.

MDF does tend to be more affordable than plywood but more expensive than chipboard.

OSB Vs. Plywood Vs. Chipboard

OSB (oriented strand board) is a type of particle board that is used commonly in residential and commercial construction.

OSB is more affordable than plywood but it’s harder to paint than chipboard.

Closing Thoughts

As you can see, both plywood and chipboard have their place.

Chipboard is more affordable and denser while plywood is stronger and suitable for load-bearing structures.

Which is the right choice for your project will therefore depend on the nature of the project.

We hope we have given you some insight into the pros, cons and differences of plywood and chipboard.

Just remember to carefully evaluate the needs of your project and refer to our article to help you make the right choice!